When we buy optical modules, depending on the operating temperature, in addition to the most common commercial grade, we can also see extended grade and industrial grade options. Why do optical modules need to be divided into so many temperature levels, and what are the differences between them?

As one of the most important parameters of the optical module, the operating temperature can affect other parameters of the optical module. When the ambient temperature of the optical module application changes, its working current and other parameters will also change, thus affecting its normal transmission, extended-grade and industrial-grade optical modules are developed for this problem.

Most common optical modules are commercial grade (C-TEMP), and their normal operating temperature ranges from 0 to +70 ℃. The extended stage (E-Temp) ranges from -20℃ to +85℃. The working temperature of industrial grade (I-Temp) is -40℃ ~ +85℃, which can work in the harsh environment of ultra-high or ultra-low temperature. In addition, the industrial optical module must be designed with scene hardened parts in terms of electrical components and housing to ensure the service life of the module.

The difference between different temperature levels of optical modules

The chip withstands different temperatures

The commercial grade optical module is 0 ℃ ~ 70 ℃, the expansion level is -20 ℃ ~ +85 ℃, and the industrial grade optical module is -40 ℃ ~ 85 ℃, which is the same as the operating temperature that can be supported.

Different test methods

Commercial grade optical modules only need to perform normal temperature aging tests, while industrial grade optical modules need to perform high and low temperature aging tests.

Different price

Due to the physical cooling and temperature compensation of industrial grade optical modules, its raw material costs and manufacturing costs increase. Therefore, in the case of the same transmission rate and wavelength parameters, the price of industrial grade optical modules is often more expensive than that of commercial grade optical modules.

Different application scenarios

Commercial grade optical module: it is the most common and widely used product in the market, generally used in enterprise networks, data centers, computer rooms and other network environments;

Extended-level optical module: It is used in relatively harsh environments with a large temperature difference, such as remote mountain areas in the field, tunnels, etc.

Industrial grade optical modules can withstand lower temperatures than extended grade optical modules, industrial grade optical modules are generally used with industrial grade Ethernet switches, and are used in industrial Ethernet application scenarios in factory automation, railway and intelligent transportation systems (ITS), power facilities substation, Marine, oil, gas, mining and other industries. Industrial grade optical modules can meet the harsh working environment of durable and stable transmission.

How to make the optical module meet industrial grade temperature standards?

Hardware compliance

The chips and lasers used in industrial optical modules must be made of products with industrial temperature grades and need to be heated at high temperatures during testing.

Temperature compensation

When the industrial optical module is operated in the low temperature below zero, in order to ensure that the optical module has a stable transmission power, it must be temperature compensation to ensure its normal operation at low temperatures.

Physical cooling

In order to meet the stable operation at high temperatures, the industrial optical module must have the self-cooling function, mainly using heat-dissipating silica gel for physical cooling, so that the heat generated by the laser can be dispersed as soon as possible.

Example: complete industrial temperature control design scheme

Industrial key chip selection

Chip selection needs to meet industrial temperature requirements;

Industrial optical device design

The optical device design meets the industrial working environment to ensure the stable optical power under extreme conditions of high and low temperatures;

COB scheme adopts copper embedded scheme at the bottom, the heat dissipation effect is better;

Add heating resistance design to meet the low temperature -40℃ operation.

Industrial grade structure design

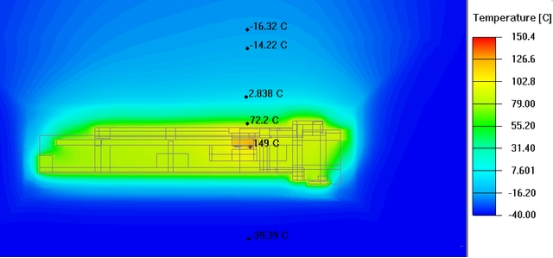

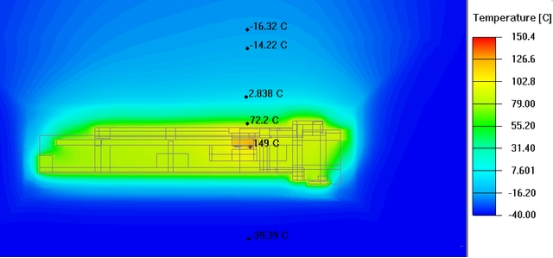

The internal structure of the optical module is designed according to the optimal heat dissipation and guaranteed by thermal design simulation;

The internal use of relatively large silicone heat sink;

Industrial grade software temperature compensation

One of the characteristics of laser is that the light output power changes with the change of temperature, and excellent wide temperature compensation software control is particularly important.

Industrial grade production process design

Industrial optical module batch conversion PVT verification yield:

If the product meets the yield of more than 90%, the BOM is defined as industrial grade product.

How to choose between industrial and commercial optical modules

In summary, the operating temperature range of industrial optical modules is larger than that of commercial optical modules, and the performance is more stable. Therefore, in outdoor environments with large temperature differences, such as base stations, industrial optical modules must be selected. Compared with commercial grade optical modules, its safety and reliability are higher; In the indoor environment where the temperature difference is relatively stable, such as the computer room, industrial grade optical modules and commercial grade optical modules can meet the actual application needs, but considering the wiring cost, choose commercial grade optical modules.

Practical application case

Ericsson baseband system interconnection application requirements

Baseband product interconnection is a more complex industrial application scenario, the ambient temperature is -40 ℃ ~ +85 ℃, and it may be the external environment of high humidity, high salt, and high fog, so the complete combination of air tightness and temperature is required.

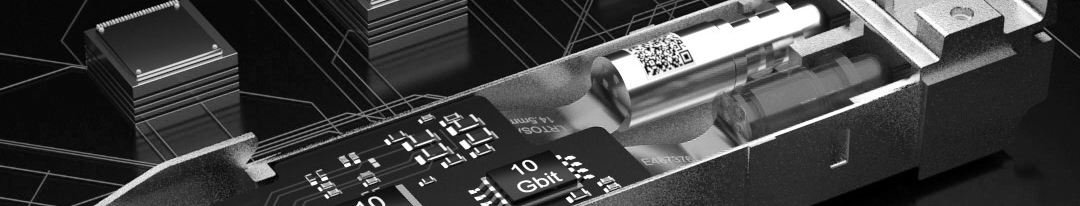

Recommended products: C-light 100G QSFP28 IND.

C-light's 100G QSFP28 IND. is an industrial-grade QSFP28 transceiver suitable for 5G Open RAN forepass applications, supporting the two-way transmission of 100G signals, using single-mode fiber, with a maximum transmission distance of 100 kilometers (ZR4).

C-light is an experienced and professional optical communication equipment manufacturer, and the technical requirements of all products are extremely demanding. Behind the trust, it is C-light's attitude towards product innovation and the pursuit of artisan spirit.

Your current position:

Your current position: