SFP+ CWDM is small form-factor pluggable with coarse wavelength division multiplexing. There are 4 types of Laser in Optical transceivers modules:

LED;

VCSEL: Advantages of VCSEL laser medicine are small size, circular output spot, single longitudinal mode output, low threshold current, low price, easy integration into large area array, etc. It is more efficient than DFB laser and FP laser at the same output power. Compared with FP lasers and DFB lasers, it is easier to fabricate and adjust the collimation CSEL, so that a low-cost CSEL-based transmitter can be produced.

FP: Fabry-perot. It is a semiconductor light-emitting device which takes FP cavity as resonant cavity and emits multi-longitudinal mode coherent light. FP laser is mainly used for low rate short distance transmission, such as the transmission distance is generally within 20 kilometers. The rate is generally within 1.25G. FP is divided into two wavelengths, 1310nm/1550nm.

At present, there are also some low-cost gigabit 40km modules made with FP devices in the market. In order to achieve the corresponding transmission distance, the transmitted light power must be increased. Long working hours will make the device of the product aging in advance and shorten the service life. According to the engineer's suggestion of a 1.25g 40km dual-fiber optical module, DFB device is more secure!

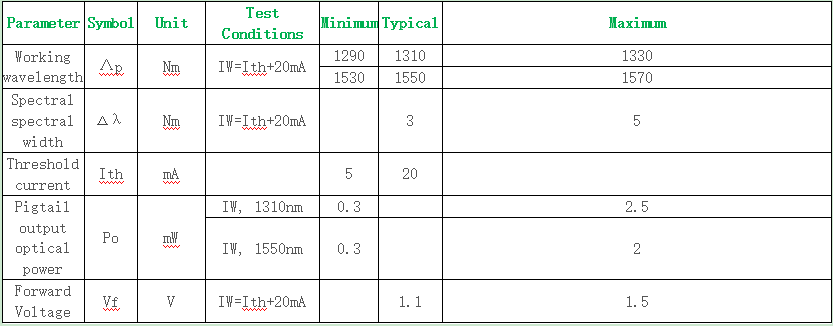

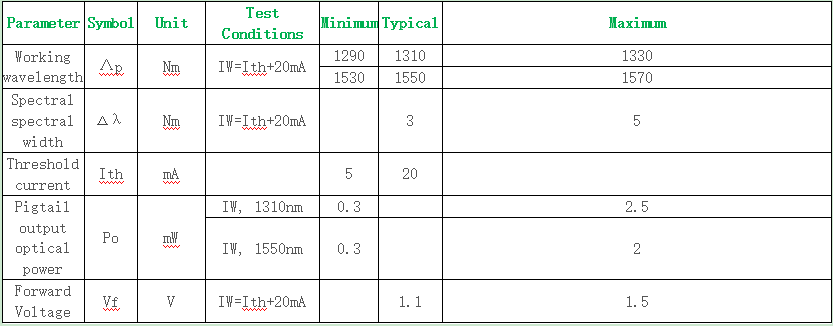

Performance parameters of FP laser:

1) working wavelength: the central wavelength of the spectrum emitted by the laser.

2) spectral width: RMS spectral width of multi-longitudinal mode laser.

3) threshold current: when the operating current of the device exceeds the threshold current, the laser emits a laser with good coherence.

4) output optical power: the optical power emitted by the laser output port.

Typical parameters are shown in the following table:

DFB: It is based on FP laser by using grating filter so that the device has only one longitudinal mode output. DFB(Distributed Feedback Laser) generally USES two wavelengths of 1310nm and 1550nm, which are divided into refrigeration and no refrigeration. It is mainly used for high-speed, medium and long distance transmission, and the transmission distance is generally more than 40km.

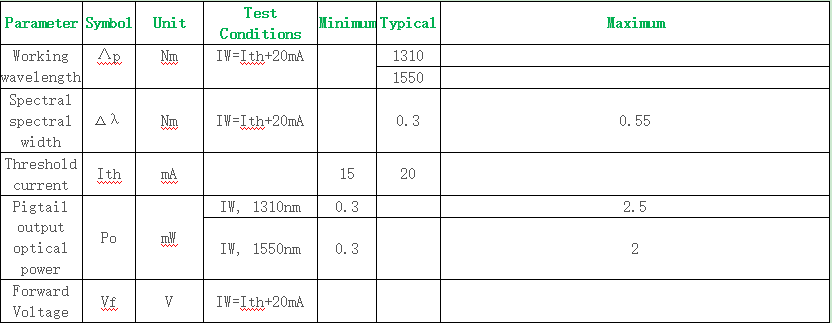

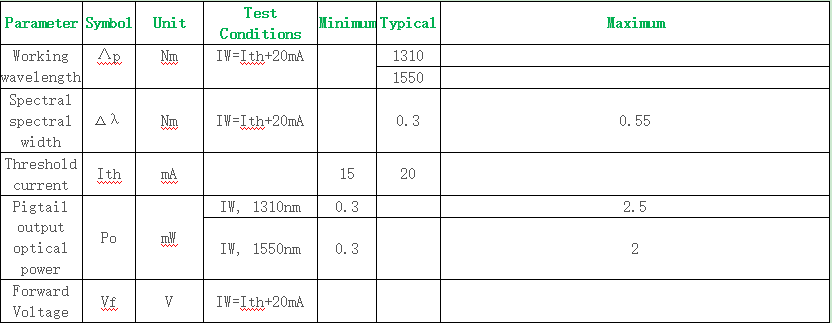

Performance parameters of DFB laser:

1) working wavelength: the central wavelength of the spectrum emitted by the laser.

2) edge-mode rejection ratio: the power ratio between the working main mode and the maximum edge-mode of the laser.

3) -20db spectral width: the spectral width at the peak of the laser output spectrum is reduced by 20dB.

4) threshold current: when the operating current of the device exceeds the threshold current, the laser emits a laser with good coherence.

5) output optical power: the optical power emitted by the laser output port.

Typical parameters are shown in the following table:

As can be seen from the above table, the main difference between FP and DFB laser is the different spectral width. The spectral width of DFB laser is generally narrow, which is the single longitudinal mode of distributed negative feedback. The spectral width of FP laser is relatively wide and it is a multi-longitudinal mode laser. Their operating wavelength, threshold current and forward voltage are also different.

A DFB (Distributed Feedback Laser) differs in that it has a built-in Bragg Grating, which is a side-emitting semiconductor laser. At present, DFB lasers mainly use semiconductor materials as the medium, including gallium antimonide (GaSb), gallium arsenide ( GaAs ), indium phosphide (InP), and zinc sulfide ( ZnS ). DFB lasers having the maximum feature is very good monochromatic (i.e. spectral purity), which can be done within the general width of 1MHz, and a very high side-mode suppression ratio ( the SMSR ), currently up to 40-50dB above.

Process structure

Manufacturing process: DFB chip manufacturing process is very complex, reflecting the most complex manufacturing process of semiconductor products. The following table shows the main production process of DFB laser (from material processing to packaging):

| Process | Back End |

|

GaSb-processing |

Cleaving |

|

Coating / lift-off |

Facet coating |

|

Optical lithography |

Characterization |

|

E-beam |

Mounting (TO-header) |

|

Vapor coating |

Fiber coupling |

|

Etching |

Burn-In |

|

Electroplating |

...... |

|

Quality control |

|

DFB chip structure design: The chip is divided into P pole and N pole. When the current injected into the pn junction is low, only spontaneous radiation is generated. When the threshold current is reached, the pn junction generates laser light.

The development direction of DFB lasers is:

A wider harmonic range and a narrower linewidth. Two independent gratings are integrated in a DFB laser to achieve a wider wavelength harmonic range, such as a 100nm harmonic range

A narrower spectral line. Finally, a DFB laser can be used to detect a variety of gases.

Longer center wavelength. From 750nm to 3500nm, and gradually to the center wavelength of 4000nm or higher;

Higher power. Due to the current DFB laser power is generally Low, high power enables a wider range of applications such as long distances and multiple paths.

Download C-light SFP+ CWDM DFB Transceiver specification:

Your current position:

Your current position: