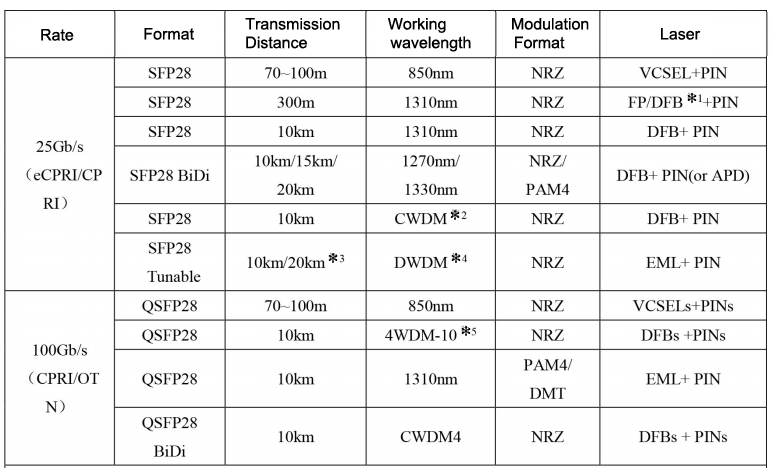

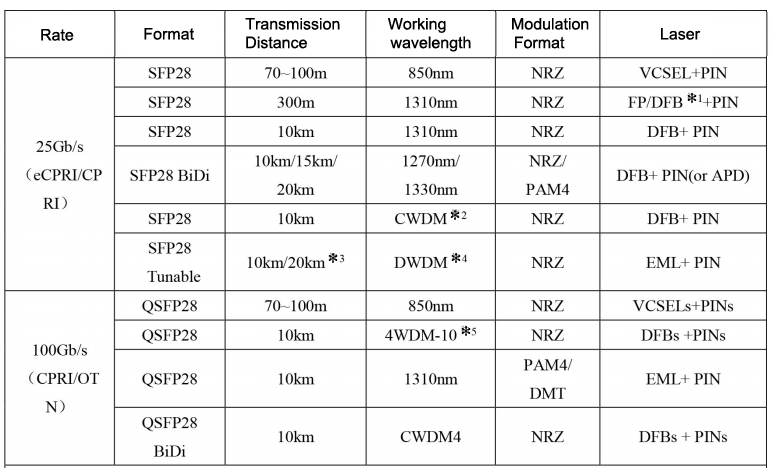

At present, the International Telecommunication Union (ITU-T), the Institute of Electrical and Electronics Engineers (IEEE), the Optical Interconnection Forum (OIF), multi-source agreements (MSA) such as 4WDM, and the China Communications Standards Association (CCSA) are under development of the formulation of optical module specifications related to 5G. It involves different module types and a variety of types of interface characteristics. The fronthaul optical module mainly includes two types of data rates of 25Gb/s and 100Gb/s, and supports a typical transmission distance of hundreds of meters to 20km. The specific technical status is shown in Table 1.

Table1

*1: Adopt 10Gb/s industrial grade FP or DFB laser

*2: The center values of CWDM working wavelengths are 1271nm, 1291mm, 1311nm and 1331nm respectively

*3: According to the link budget, optical amplifier and dispersion compensator can be configured;

*4: DWDM working wavelength meets ITU-tg694.1 wavelength definition

*5: The center values of four working wavelengths of 4wdm10 are 1271mm, 1291mm, 1311nm and 1331nm respectively

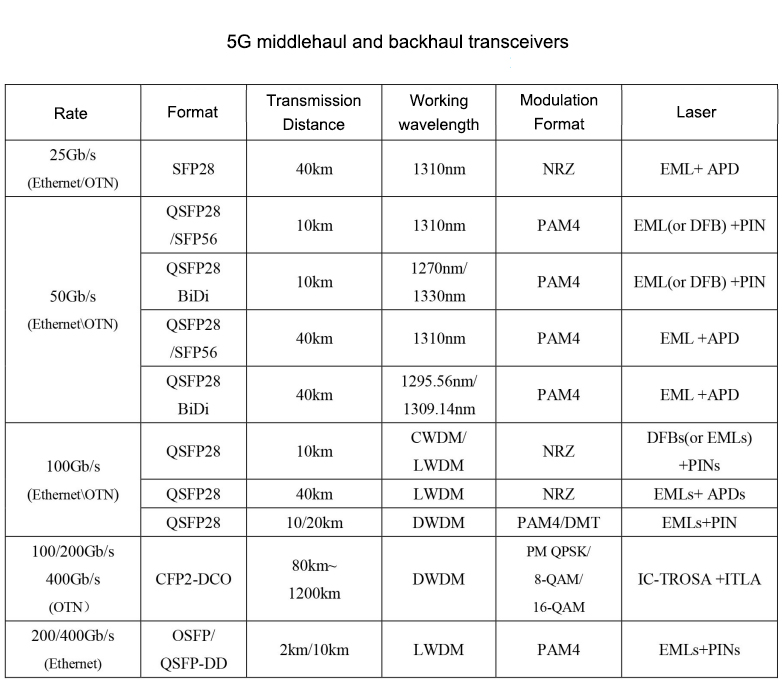

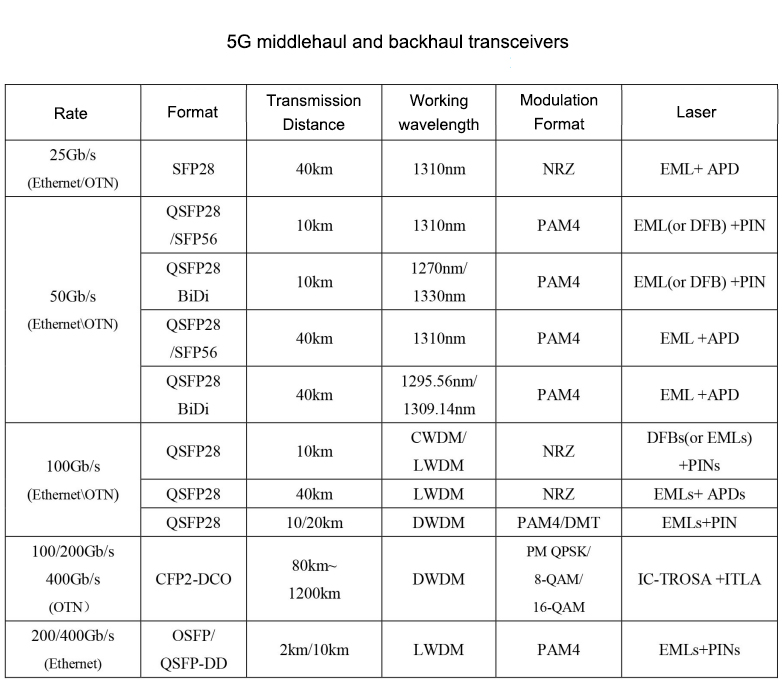

5G backhaul optical modules mainly include 25Gb/s, 50Gb/s, 100Gb/s, 200Gb/s, 400Gb/s and other speeds. Typical transmission distances range from several kilometers to hundreds of kilometers, supporting CPRI, eCPRI, Ethernet, OTN and other interface protocols, as well as NRZ, PAM4, DMT and other modulation formats, the specific technical status is shown in Table 2.

Table 2

With the development of optical device chip technology, standards and application requirements, the types of optical modules may increase in the future. Too many product types and specifications will lead to fragmentation of the overall optical module industry market, resulting in waste of resources in the upstream and downstream research and development, manufacturing, operation and maintenance of the industrial chain.

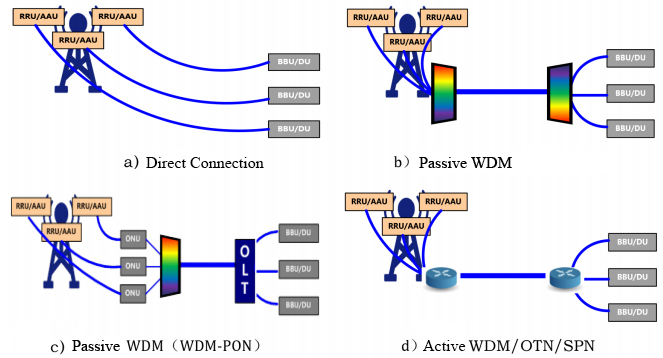

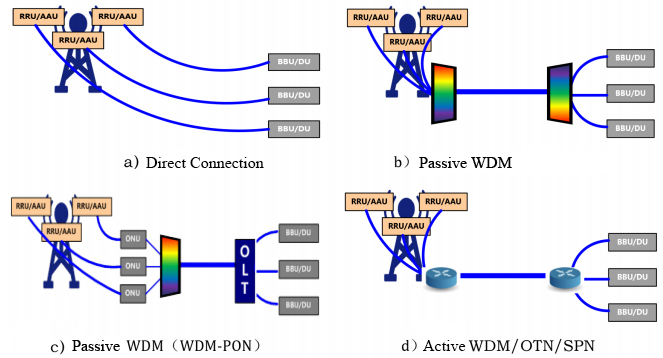

Typical application scenarios of 5G fronthaul

Typical application scenarios of 5G fronthaul are shown in Figure 1, including direct fiber connection, passive WDM, and active WDM / optical transport network ( OTN ) / slicing packet network (SPN). Direct fiber connection scenarios generally use 25 Gb/s gray light modules, which support two types of dual-fiber and single-fiber two-way, mainly including two transmission distances of 300m and 10km. Passive WDM scenarios mainly include point-to-point passive WDM and WDM-PON, etc., using a pair or one fiber to achieve the connection between multiple AAUs and DUs, typically requiring 10Gb/s or 25Gb/s color optical modules. In active WDM / OTN scenarios, 10Gb/s or 25Gb/s short-range gray-light modules are generally required between AAU / DU to WDM / OTN / SPN equipment, and N × 10/25/50Gb/s is required between WDM / OTN / SPN equipment. / 100Gb/s double-speed bi-directional or single-fiber bi-directional optical module at the same rate.

Figure 1 | Typical application scenarios of 5G fronthaul

Typical requirements for optical modules in 5G fronthaul application scenarios are as follows:

(1) Meet the industrial temperature range and high reliability requirements: Considering the AAU full outdoor application environment, the front-end optical module needs to meet the industrial temperature range of -40°C to + 85°C, and dustproof requirements.

(2) Low cost: The total demand for 5G optical modules is expected to exceed 4G . In particular, front-end optical modules may have tens of millions of demands. Low cost is one of the major demands of the industry for optical modules. In 5G, the backhaul covers the metro access layer, convergence layer and core layer. The required optical modules are not significantly different from those used in existing transmission networks and data centers . The access layer will mainly use 25Gb/s, 50Gb/s, 100Gb/s and other gray light or colored light modules, the convergence layer and above will mostly use DWDM colored light modules with 100Gb/s, 200Gb/s, 400Gb/s and other speeds.

The optical transceiver module consists of an optical transmitter and an optical receiver. The function of the optical transmitter is to convert the electrical signal into an optical signal, which is composed of a laser drive circuit and a power control circuit. The laser is driven to generate an NRZ encoded optical signal by a direct modulation. The optical receiver is composed of a photodetector trans resistance amplifier and a limiting amplifier to convert the optical signal into an electrical signal. The photodetector converts the received optical signal into a tiny current signal. The trans resistance amplifier converts the tiny current signal into a voltage signal limiting amplifier, which limits the signal voltage to a certain range and outputs it through the output terminal.

The packaged hot pluggable optical module includes optical transmission and receiving functions and can provide alarm functions required by the system. Its electric end is connected by gold fingers, and the optical end uses high-performance LC connector. The whole module size is only half of that of the ordinary duplex SC (1x9) optical module, which has the characteristics of small size, reasonable structure, convenient and flexible use. In the same space, the number of optical ports can be increased by times, It can increase the line port density and reduce the system cost of each port, so it is widely used in various switch ports.

Hot plug in transceivers

The so-called hot plug simply means to plug in or pull out the optical module when the system is not shut down, and to ensure that all parts of the system work normally during and after the hot plug process. Hot plug can reduce the power down time caused by system maintenance and upgrade. Ordinary optical modules do not have hot plug function. Each maintenance or upgrade must turn off the power supply of the equipment until the plug-in process is completed. However, due to the importance of the telecommunication and data communication system, long-time power outage is not allowed. Moreover, the restart time of many existing operating systems is long, Therefore, hot plug technology has become more and more important in the field of communication applications. The market demand for hot plug optical modules is more and more urgent. At present, there are many hot pluggable optical module products at home and abroad, but few articles introduce the hot pluggable technology of optical module.

When the optical module is hot swapped, the following problems should be considered and solved.

(1) Safety of laser. Laser is the most important and expensive component in optical module, and how to ensure that the laser is not damaged in the process of hot plug is the key of hot plug technology.

C-light 100G 40km transceiver video

(2) Surge current. When the optical module is inserted into the electrified backplane, the filter capacitance of the power supply chip on the optical module circuit board is in the low resistance state, and the transient impact current from the backplane to the circuit board is very high, which may burn the connector or the components on the board.

Your current position:

Your current position: