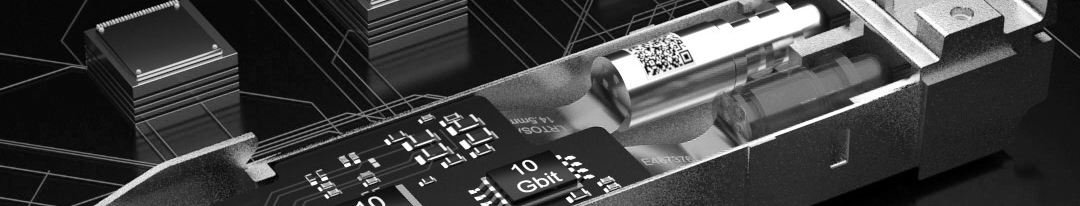

In DWDM SFP+ optical transceiver module with EML, tunable laser represents an important kind of technology.

Previous article on DWDM and WDM: Advantages of WDM as high stage in optical communication

Tunable laser means that the output wavelength of a laser can be continuously changed within a certain range. Compared with other traditional solid-state lasers, tunable lasers have a wide range of tunnages ranging from near ultraviolet to near infrared, and are small in size, narrow in width and high in optical efficiency.

Working principle

There are basically three principles for laser wavelength tuning. Most tunable lasers use a wide range of fluorescent lines. The cavity of a laser can only be very low in a very narrow wavelength range. Therefore, the first is to change the wavelength of the laser by changing the wavelength corresponding to the low loss region of the resonator through some components, such as grating. The second is to change the laser by changing some external parameters, such as magnetic field and temperature transition Of energy level Mobile. The third way is to make use of nonlinear effect to achieve wavelength conversion and tuning (see nonlinear optics, Stimulated Raman scattering, Optical two frequency doubling, Optical parametric oscillations). Typical lasers with the first tuning mode are available (dye laser, Gold Emerald Laser, Color center laser, Tunable high pressure gas laser and Tunable excimer laser)

Technical classification

From the point of view of realization technology, tunable lasers are mainly divided into current control technology, temperature control technology and mechanical control technology.

The electronic control technology is to achieve wavelength tuning by changing the injection current. It has ns tuning speed and wide tuning bandwidth, but the output power is small. Based on the electronic control technology, there are mainly SG-DBR (sampling grating DBR) and GCSR (auxiliary grating orientation coupling Backward sampling reflection) laser. The temperature control technology is to change the laser. Active region Refractive index, thus changing the output wavelength of the laser. The technology is simple, but with slow speed and adjustable bandwidth, with only a few nm. DFB (Distributed feedback) and DBR (distributed Bragg reflector) laser are mainly based on temperature control technology. Mechanical control is mainly based on MEMS (MEMS The technology completes the wavelength selection, with larger adjustable bandwidth and higher output power. Based on mechanical control technology, there are mainly DFB (distributed feedback), ECL (external cavity laser) and VCSEL (vertical cavity surface emitting lasers) and other structures. The tunable principles of lasers can be explained from these aspects.

Previous article: DFB in SFP+ CWDM reflects the most complex manufacturing process of semiconductor products

Differences between VCSEL and other lasers in SFP

Based on current control technology

The general principle of current control technology is to change the different positions in tunable lasers. Fiber Bragg grating and phase control part of the current, so that the relative refractive index of fiber Bragg grating will change, produce different spectra, through different regions of fiber Bragg grating generated by different spectral superposition to select the specific wavelength, thus producing the required specific wavelength of laser.

A tunable laser based on current control technology adopts SGDBR (Sampled Grating Distributed Bragg Reflector) structure.

This type of laser is mainly divided into semiconductor amplification area, pre Bragg grating region, activation region, phase adjustment region and post Prague grating area. The former Bragg grating The region, phase adjustment area and post Bragg grating region change the molecular distribution structure of the region by varying the current, thereby changing the periodic characteristics of the Bragg grating.

For the spectra generated in the activated region (Active), the spectra with smaller frequency distributions are formed in the front Bragg grating region and the rear Bragg grating region respectively. For a specific wavelength laser, a tunable laser applies different currents to the front Bragg gratings and the back Bragg gratings, so that the two wavelengths produce overlapping wavelengths of other wavelengths, so that the specific wavelength can be transmitted. At the same time, the laser also contains a semiconductor amplifier region, so that the output specific wavelength of the laser power reaches 100mW or 20mW.

Based on mechanical control technology

Generally, mechanical control technology is adopted MEMS To achieve. A tunable laser based on mechanical control technology adopts MEMs-DFB structure.

Tunable lasers mainly include DFB Laser Array, tilted MEMs Lenses and other control and auxiliary parts.

There are several DFB laser arrays in the DFB laser array area. Each array can generate a specific wavelength of 25Ghz at a bandwidth of about 1.0nm. By controlling the rotation angle of the MEMs lens, the specific wavelength needed is selected to output the specific wavelength needed.

The other tunable laser based on VCSEL structures with a series of ML is designed on the principle of Optically pumped Vertical cavity surface emitting laser. using semi symmetric cavity Technology and MEMS, Continuous wavelength tuning is achieved. At the same time, large output optical power and wide spectral tuning range can be obtained by this method. Thermistor It is packaged with TEC to provide a stable output in a wide temperature range. For precision frequency control A broadband wavelength controller is integrated into the same shell, and the front end is connected with a light power detector and an optical isolator to provide stable output power. This tunable laser can be used in C band And L band to provide 10/20mW optical power.

The main drawback of tunable lasers for this principle is that the tuning time is relatively slow, and generally takes several seconds to tune the stabilization time.

Temperature control technology

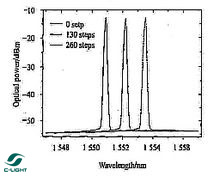

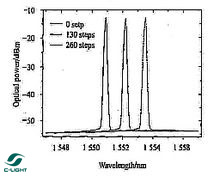

Mainly based on temperature control technology. DFB The principle of the structure is to adjust the temperature inside the laser cavity, so that different wavelengths can be emitted.

Based on this principle, the wavelength control of tunable lasers depends on the control of InGaAsP. DFB Laser The work is realized at -5--50 C. The module is built with FP etalon and optical power detection, and the continuous light output laser can be locked on the grid with 50GHz spacing specified by ITU. There are two separate TEC in the module, one used to control the wavelength of the laser, and the other is to ensure the wavelength locker and the power detector in the module work at constant temperature. The module also has SOA built in to amplify Optical output power.

The drawback of this control technology is that the width of a single module is not wide enough, generally only a few nm, and the tuning time is relatively long. It usually takes several seconds to tune the stabilization time.

At present, tunable lasers basically use current control technology, temperature control technology or mechanical control technology. Some suppliers may adopt one or two of these technologies. Of course, with the development of technology, other new tunable laser control technologies are likely to emerge.

Your current position:

Your current position: