According to different application environments, optical modules can be divided into data center-level and telecommunication-level. The telecommunications market uses harsh and harsh environments, and requires high reliability and low cost for optical modules; data center-level optical modules have lower performance requirements than Carrier-grade, such as temperature requirements, but also has the characteristics of high speed requirements, rapid iteration and large demand, and requires packaging processes that are more suitable for the needs of the data center market.

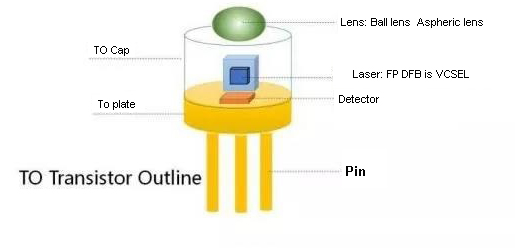

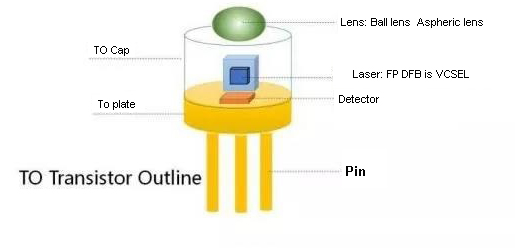

TOSA (Transmitting Optical Sub-assembley) is the main component of the Optical transmitter module, which is used to transfer electrical signals to Optical signals. In which the light source (semiconductor light-emitting diode or laser diode) is the core, the LD chip, monitoring photodiode (MD) and other components are packaged in a compact structure (TO coaxial package or butterfly package), which then constitutes TOSA.

In TOSA, LD laser diode is currently the most commonly used semiconductor emitting device for optical modules. It has two main parameters: threshold current (Ith) and slope efficiency (S). To make the LD work quickly, we have to supply the LD with a DC Bias current IBIAS (DC Bias in the figure above) that is slightly greater than the threshold current, i.e. the laser is fired only when the forward current exceeds the threshold current.

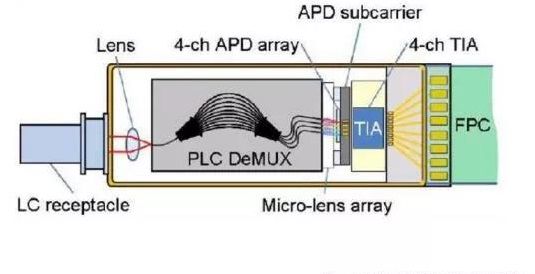

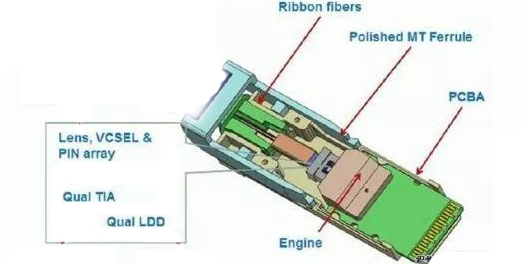

The basic structure of the optical module package is the optical transmitter-side module (TOSA) and drive circuit, the optical receiver-side module (ROSA) and the receiving circuit. The process of packaging the laser and detector into TOSA and ROSA is the core and main part of optical module packaging. Technical barriers. TOSA/ROSA 's packaging process types mainly include : TO-CAN coaxial packaging, butterfly packaging, COB packaging, BOX packaging and FlipClip .

The TO-CAN package is an airtight package. The laser die and the backlight detection tube are bonded on the heat sink, and are interconnected with the outside through bonding, and are mainly deployed in 10G optical modules.

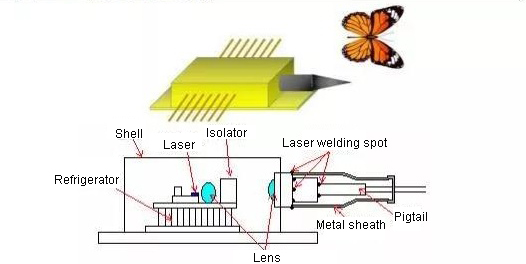

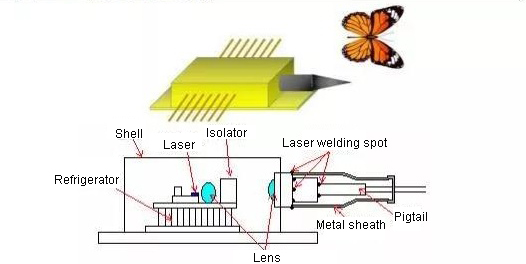

The butterfly package integrates semiconductor lasers, refrigerators, thermistors and other components in a metal package, and then couples the optical signal from the laser to the optical fiber through a certain optical system, which is used for various speeds and 80km length distance transmission.

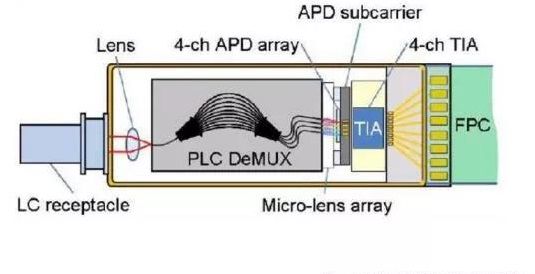

The BOX package is a butterfly package. It is used for multi-channel parallel package. It can be made into air-tight and non-air-tight packages. It is often used for medium and long-distance high-speed optical equipment transmission, and the price is relatively expensive.

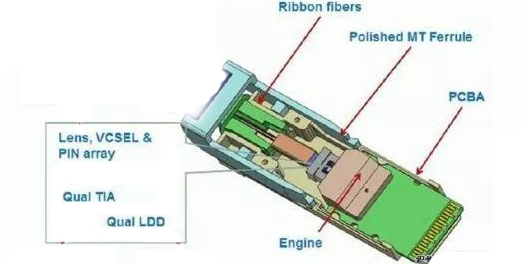

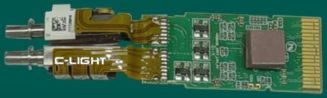

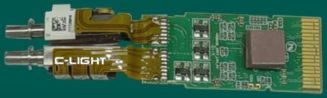

COB packaging is chip-on-board packaging. The laser chip is directly adhered to the PCB , saving PCB area and cost at the same time. Due to the construction of a shorter interconnection path, the performance is also improved. However, it should be noted that there are still technical difficulties in the precise positioning and bonding of the COB package to the chip, and the yield rate of the optical module is not the best, so special attention should be paid to the performance test of the optical module. Also, this type of packaging brings reliability problem: the LD chip is not working in airtight package, chip age could be shorter greatly during working. And reliability is a concern of customers.

C-light COB PCBA

C-light COB PCBA

On the whole, butterfly packaging is of the best performance, highest price and biggest size. COB packaging meets the requirements of low cost. Performance of box packaging is better than that of TO-CAN and COB but its price is also high. TO-CAN is of best cost versus performance. C-light provides optical modules of above 4 packaging type. Faced with the problem of product yield, C-light has strictly controlled quality of transceivers in various rate through multiple compatibility testing procedures to ensure pass ratio of products.

Your current position:

Your current position: